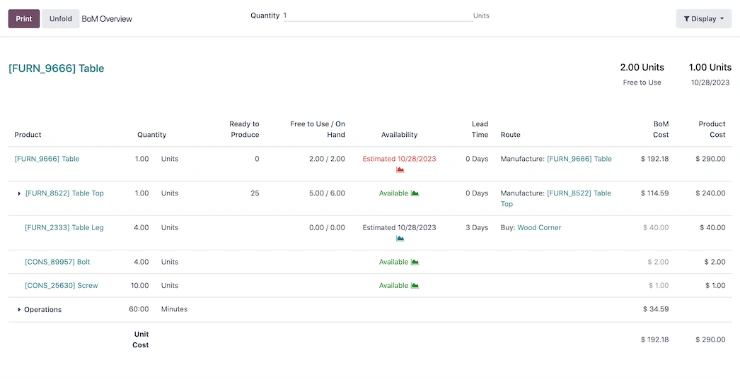

simulated operations

Simulate manufacturing orders with real-time capacity planning, components availability, and cost control.

Get just-in-time replenishment propositions and choose how to fulfill parts: make or buy, sub-contract, deliver from another warehouse, etc.

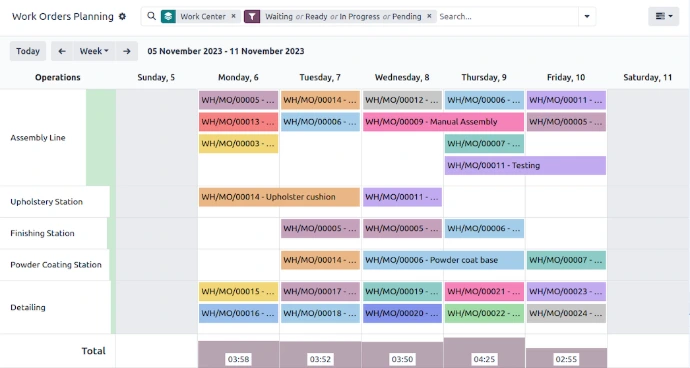

win Planning that puts you ahead of schedule

Schedule manufacturing orders and plan resources with finite capacity planning.

Fine tune easily with the Gantt chart.

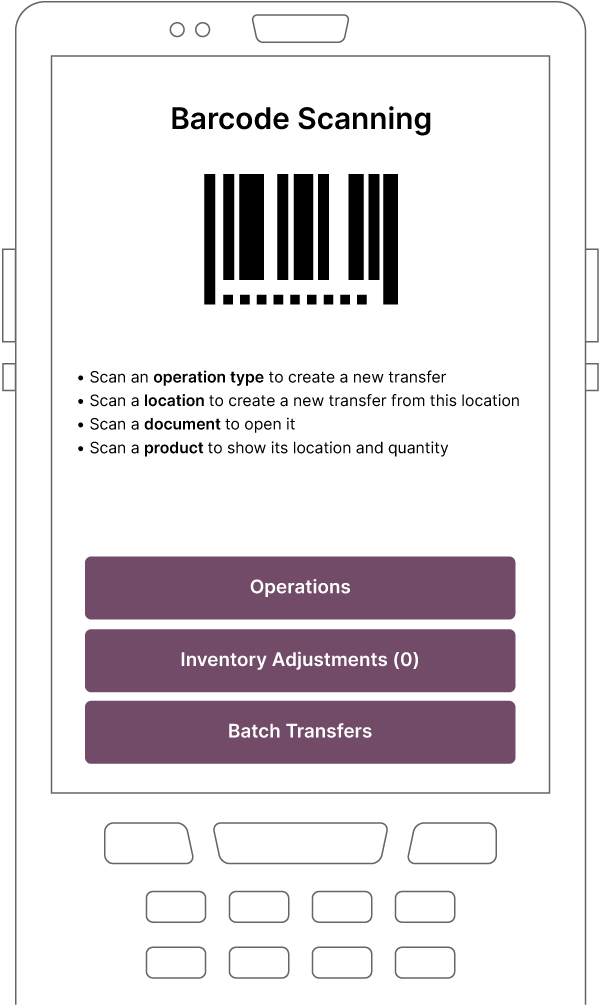

Record production and components

Use to process orders, accelerate operations, and reduce input errors. Works right out of the box, blazing fast, and with no latency.

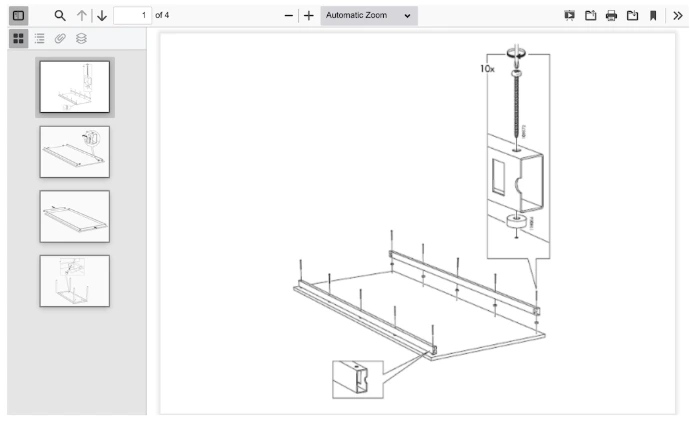

Become a paperless company

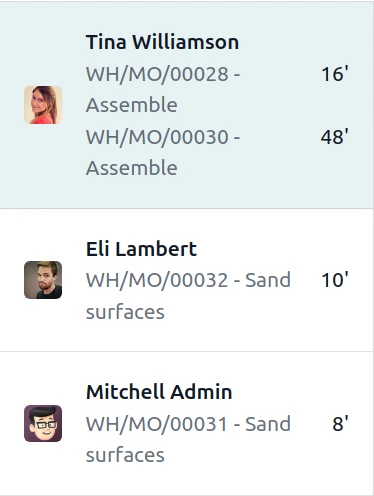

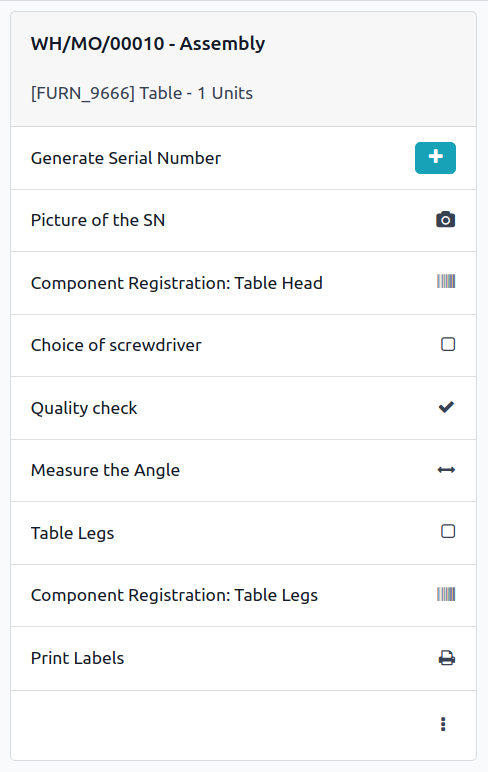

The Shop Floor app helps streamline your manufacturing line. Through the tablet-optimized dashboard, you can organize workers, workcenters, worksheets, quality tests, and much more.

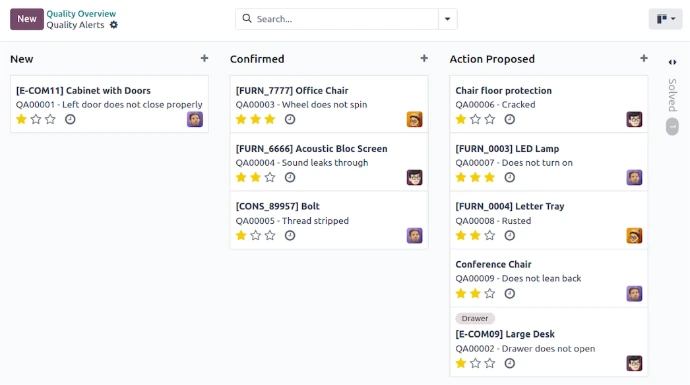

Get ready for Six-Sigma level 6!

Get statistical analysis of quality issues, and set control point instantly available in the shop floor with instructions.

Workers can send feedback through the app as they notice waste in the manufacturing process. When ideas and information flow that smoothly, quality is raised to another level...